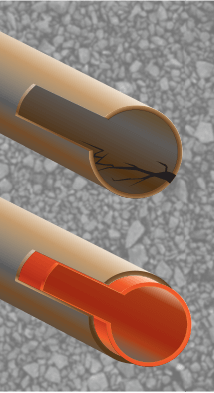

Replacing pipes can be an expensive process, costing as much as 70% more than lining them.

Reconstruction costs for repairs can be up to 60% of repair costs – and pipe lining eliminates the need for reconstruction. Up to 75% of the original flow capacity can be lost over time due to erosion of old pipes.

Safe & Durable

The materials used in pipe lining are approved by the National Sanitary Foundation (NSF) which certifies anything relating to food consumption.

Because pipes lead to lakes and the ocean, where many lifeforms exist, we use an odorless resin that has been approved by the Environmental Protection Agency (EPA).

Minimal Downtime

Epoxy lining takes a fraction of the time of traditional re-piping methods.

Minimal Invasion/Zero Displacements

Because the pipe lining process is non-invasive (meaning we don’t tear your home or property apart), quiet, and quick – it is very rare that a building’s occupant be displaced.

Versatile

Cured in place – pipe lining is a new inner load-bearing pipe, allowing the older hose pipe to deteriorate completely. Epoxy lining can be applied to any metal pipe, in any building, structure, or environment. Pipe lining can be used above or below ground level.

Pipe lining has been used in the piping systems of hotels, high-rise condos, hospitals, restaurants, schools, museums, airports, industrial & commercial businesses, and even on U.S. Navy Ships.

The pipe lining alternative is available for hot water re-circulation systems, potable water pipes, fire sprinklers and fire suppression systems, chiller lines, & HVAC systems.